-

International Brand Certification

A series of high-quality products have brought our company a well-deserved global reputation.

-

Years of Production Experience

Our years of production experience, to bring you better products and services, so that you can use at ease

-

Advanced Reputation Requirements

Strict product quality testing, to give you high-quality, high-quality products, to ensure the company's high reputation

About SUNINC

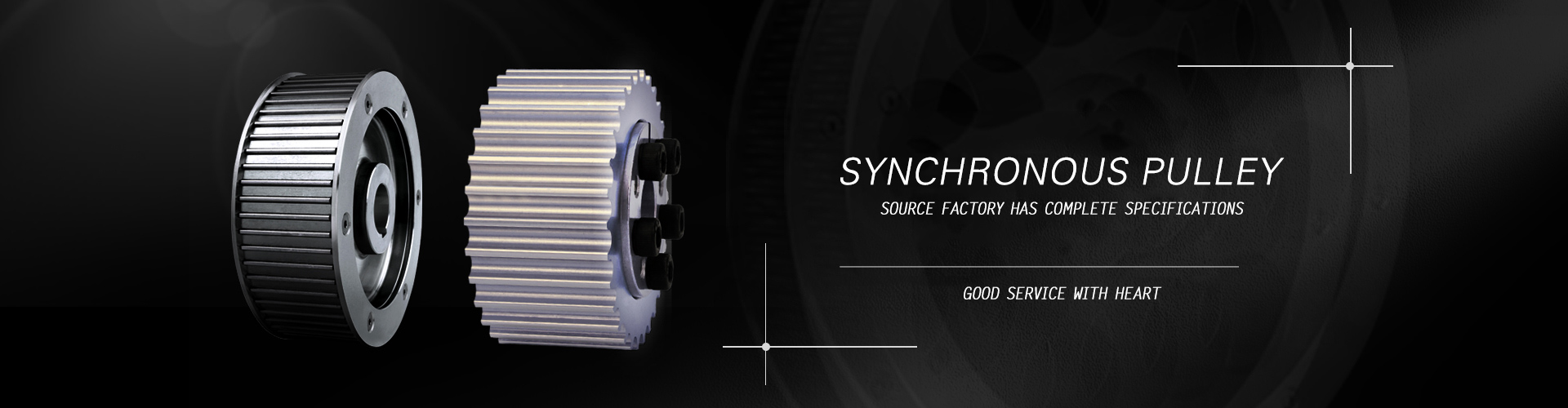

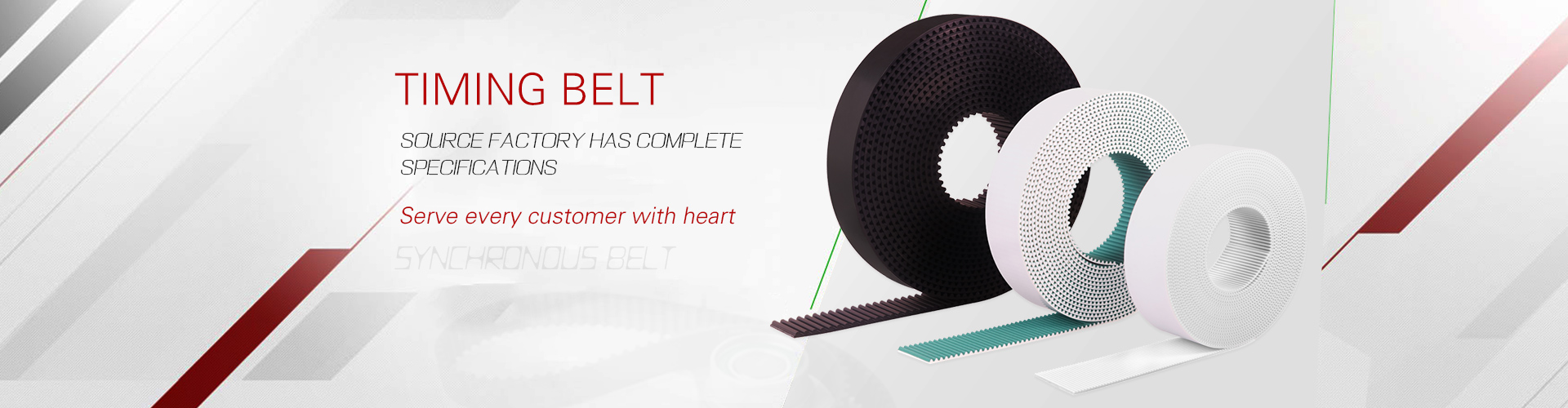

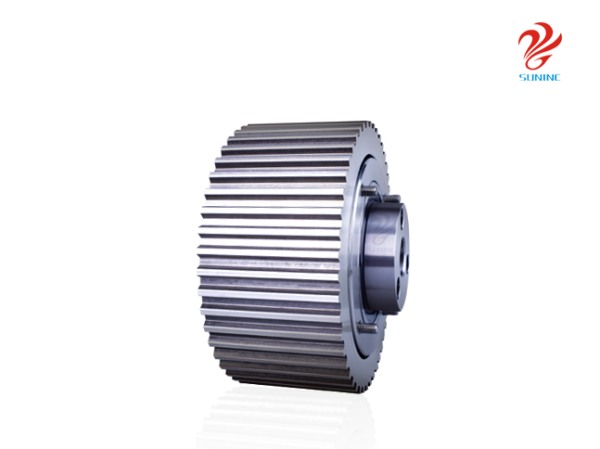

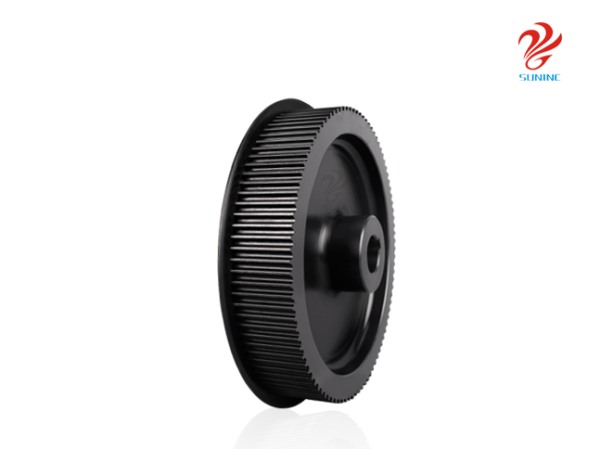

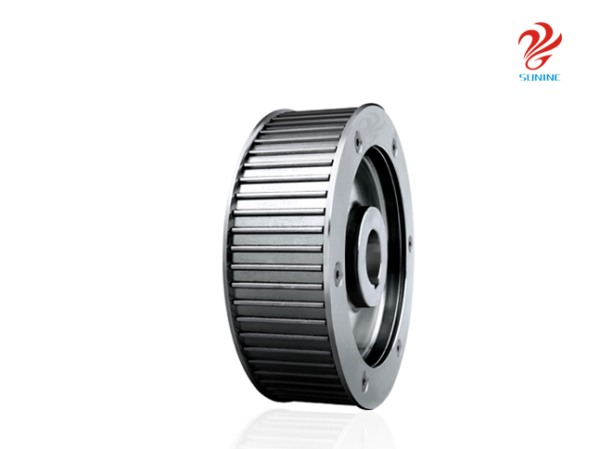

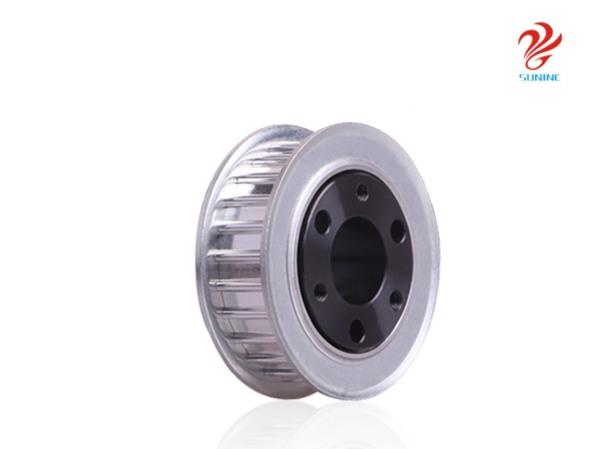

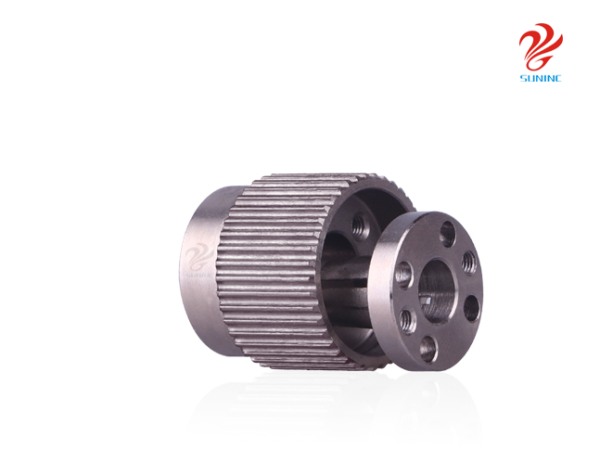

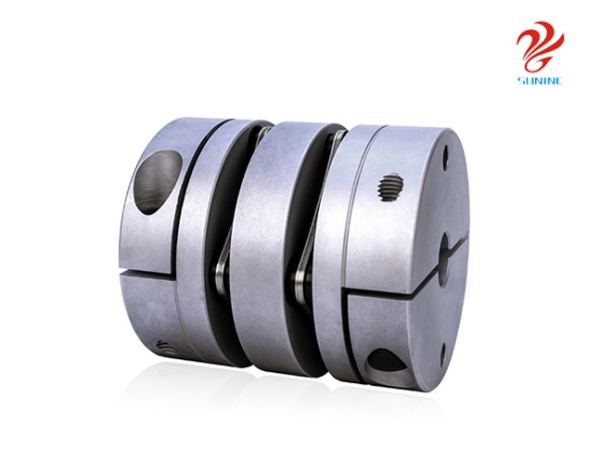

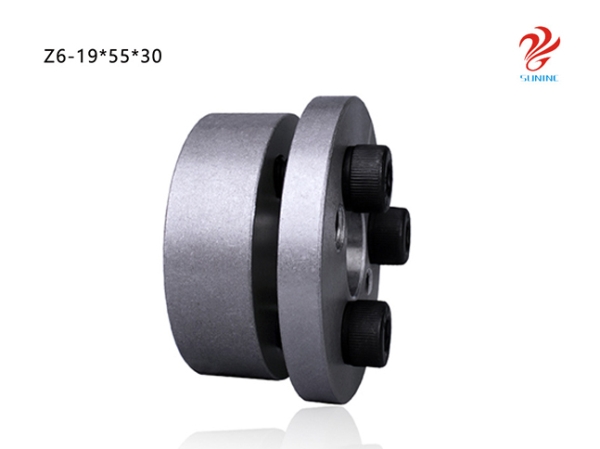

SUNINC Company - --- Chinese professional mechanical transmission products (synchronous pulley, synchronous belt, expansion sleeve, coupling) package manufacturers!

SUNINC's ideal is to become an influential manufacturer of transmission product package in China. In ten years, we have helped thousands of enterprises in the mechanical automation equipment industry to apply our high-quality transmission product package.

ADVANCED MENCHANICAL

High-end quality transmission

Quality Makes a Brand, Seiko Makes Great Achievements

People-oriented, honest management, homogeneous price, quality at the same price

Hot Selling Telephones in China

020-31528613

SUNINC Machinery

Quality Promotes Brand Seiko has made brilliant achievements

-

01

Ten years'experience creates quality

Quality makes a brand, Seiko achieves brilliant achievements; people-oriented, honest management, homogeneous price, quality at the same price.

-

02

Professional Design Concept

After receiving customers'business needs, the first thing is to communicate with customers and understand their specific requirements.

-

03

High quality after-sales service

Win infinite business opportunities of logistics socialization with high quality service, and open up a brand-new mode of machinery and equipment industry with service innovation.

-

04

Customer coverage worldwide

Our products are sold nationwide and globally, and our industrial base has developed well.

-

05

Super high cost performance ratio

We produce transmission parts with high market performance and price, and have a complete set of solutions to win the praise of our customers.

Customer satisfaction is our greatest pursuit

Create the leading and best-selling international brand of mechanical equipment transmission parts in China

SUNINC Machinery Manufacturing is a manufacturing enterprise which integrates R&D, production and sales of mechanical transmission parts. Advanced production equipment, perfect testing means, strict quality management, according to the needs of different customers to design and manufacture special specifications of products.

In recent years, the company has always adhered to the development and construction of "people-oriented, honest management, homogeneous price, quality at the same price", striving to provide customers with the best transmission products.

Phone:18903060233

Email:lrj@suninc.com.cn

Wechat Official Acconuts

Wechat Official Acconuts